Molding for the Medical Industry Since 1992

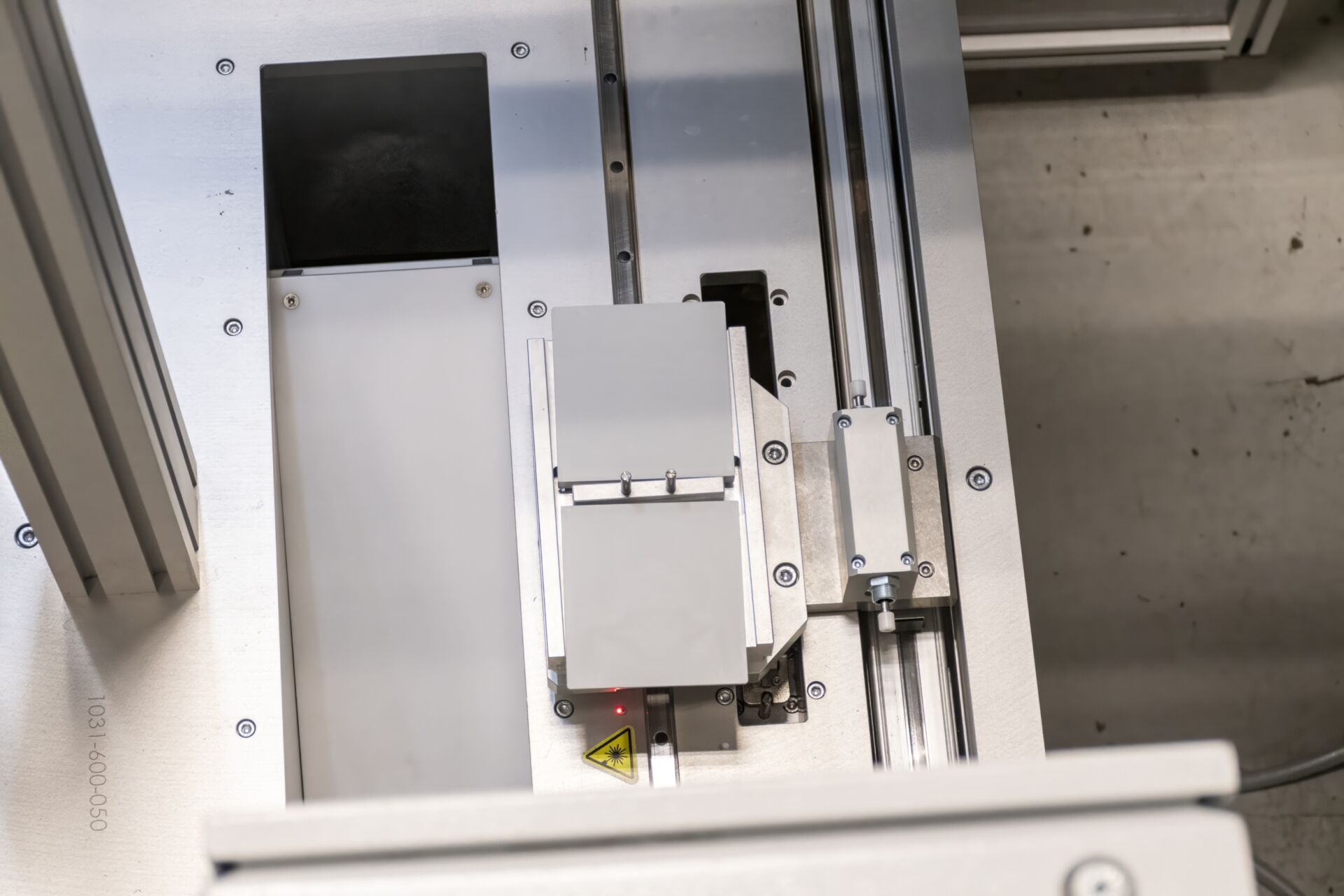

Our experience in mold design and process development delivers high-quality, high-performing molded parts that accurately and repeatedly meet even the most demanding specifications. Forum has over 30 years of experience offering superior injection molding services specializing in medical injection molding to support Class I, II(b) and III devices. Our expertise and repeatable processes only serve to benefit the other diverse markets and products we support.

Materials We Use (Filled and Unfilled)

- ABS, PC/ABS, polycarbonate

- Nylon, acetal, acrylic

- Polyethersulfone

- Polypropylene, polyethylene

- Polyarylamide, PEEK

- Polyphthalamide

- TPE/TPU

- Other medical or engineering-grade materials per request

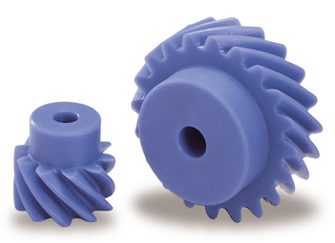

Precision Plastic Gears

Forum has experienced engineers and technical staff to produce high-quality plastic molded gears that accurately and repeatably meet even the most demanding specifications. Plastic gears are growing larger, more precise, more complex in geometry, and more powerful. High-performance resins and long-fiber compounds are aiding this evolution.

Complementary Capabilities & Applicable Markets

Forum can manage molding, printing, purchasing and assembly so that you receive one item, inspected and certified. Learn more about our contract manufacturing and complimentary services below.